Wixhc Brand 5axis Wireless jog pendant CNC Remote Control MPG Pendant for Fanuc Siemens Mitsubishi CNC Systems

Keyword:

wireless Jog Pendant

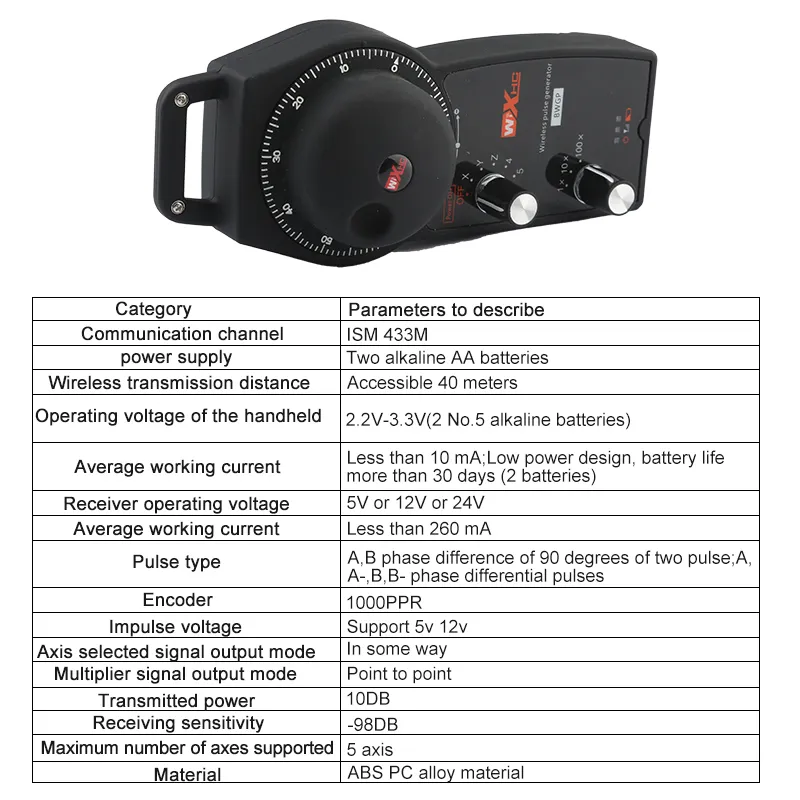

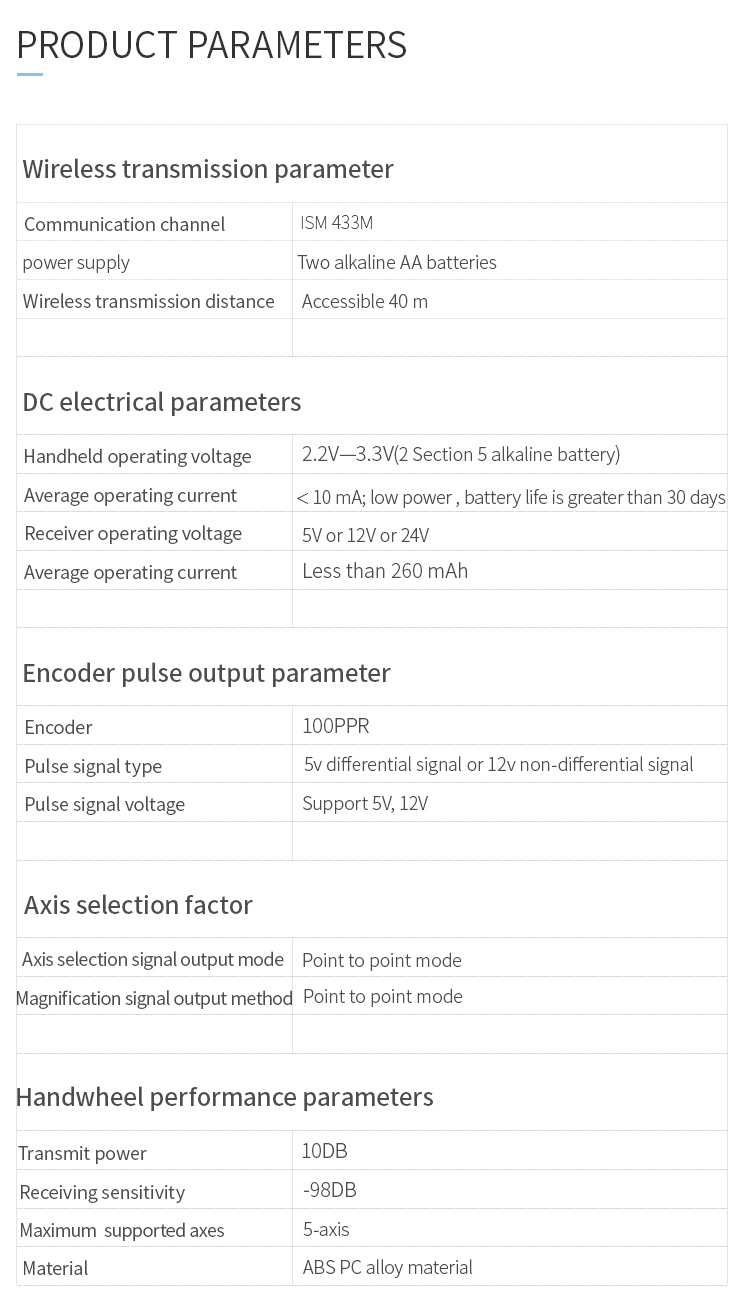

BWGP Wireless Handwheel Pendant is a 5axes handwheel ,it has black encoder and aluminum encoder for choice.

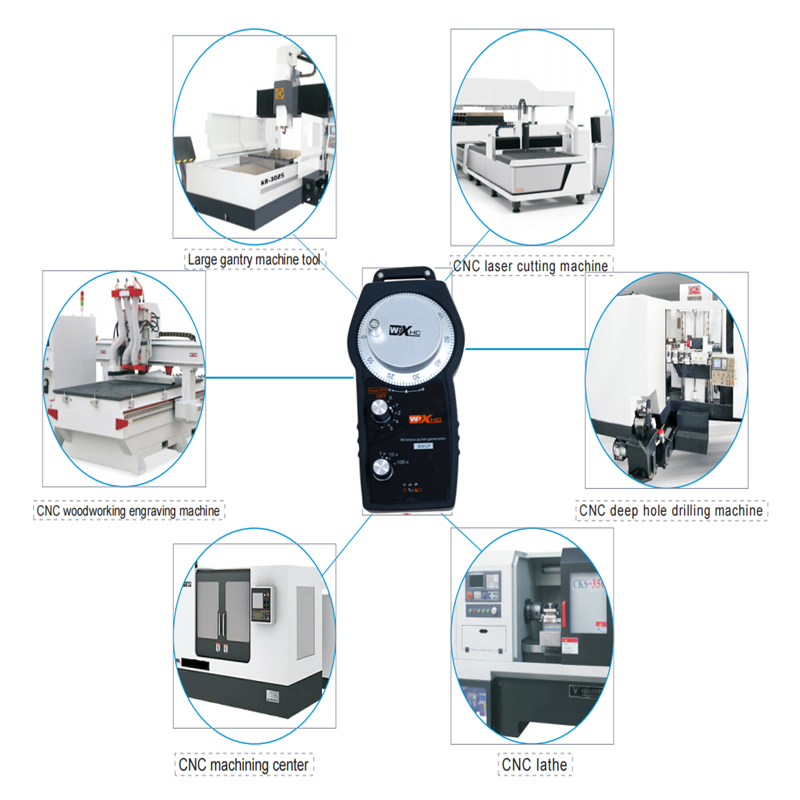

This product is a manual pulse generator used with CNC machine tools. It has been widely used in fields such as CNC machine tools, CNC lathes, machining centers, CNC engraving and milling machines. This product uses wireless transmission technology, eliminating the need for traditional spring wire connections, reducing equipment failures caused by cables, eliminating cable drag, oil and other contamination, and making operation more convenient. The product package includes the receiver and wireless electronic handwheel. The receiver is connected to the CNC equipment through a network cable, and the electronic handwheel (hand pulse generator) is connected and communicated with the receiver through wireless transmission technology. The operator holds the handwheel and can get rid of the connection constraints of the spring wire and move freely. For large-scale gantry milling, CNC lathes, traveling machine tools, cutting and other applications, it brings great convenience and improves work efficiency.

Support system Supports various system brands such as Siemens, Mitsubishi, Fanuc, Taiwan Xindai, Baoyuan, Fagor, Huazhong CNC, Guangzhou CNC, and otherCNC systems that support handwheel interfaces. Features 1. Using the 433MHZ wireless communication frequency band, the wireless operating distance is 40 meters; 2. Adopt automatic frequency hopping function and use 32 sets of wireless handwheels at the same time without affecting each other; 4. Supports 5V differential pulse signal, 24V pulse signal and other pulse signal types; 5. Low power consumption design, 2 AA batteries can be used for more than 1 month; 6. Supports external extension antenna, , suitable for various machine tool installation environments, ensuring signal stability;

The integration of wireless jog pendant technology has brought substantial improvements to industrial control systems across various sectors. As a flexible remote control solution, this equipment eliminates the physical constraints associated with traditional wired pendants, offering operators enhanced mobility during machinery operation. The fundamental advantage lies in its ability to maintain reliable communication with controlled equipment while allowing freedom of movement within designated operational areas. This technology has proven particularly valuable in environments where operators need to maintain visual contact with complex procedures from multiple angles, or where cable management presents logistical challenges in large-scale industrial settings.

Operational efficiency receives significant boosts through the implementation of a well-designed wireless jog pendant. The absence of cables removes potential trip hazards in busy work environments while eliminating issues related to cable wear, tear, and connector damage that often plague traditional wired solutions. Operators can position themselves at optimal vantage points during precision tasks, resulting in improved accuracy and reduced setup times. The flexibility afforded by these systems enables single operators to manage multiple machines from central locations, streamlining workflows in manufacturing cells and production lines where equipment may be distributed across considerable floor space.

Safety represents another domain where the wireless jog pendant demonstrates clear benefits. Modern units incorporate multiple safety layers including robust emergency stop functions, signal monitoring systems, and battery level indicators that provide advanced warnings for necessary recharging. The wireless nature allows operators to quickly distance themselves from potentially hazardous situations while maintaining full control over equipment. Furthermore, these systems typically include fail-safe mechanisms that automatically halt machine operation if communication is interrupted or signal strength drops below acceptable thresholds, ensuring reliable performance in critical applications.

The versatility of contemporary wireless jog pendant designs extends their applicability across diverse industrial sectors. From crane operations in manufacturing facilities to robotic welding cells and CNC machining centers, these devices provide consistent control interfaces that operators can master and apply across different equipment types. Many models feature customizable button configurations and programmable functions that can be tailored to specific operational requirements. This adaptability makes them suitable for everything from heavy industrial applications to precision tasks in cleaner manufacturing environments, with designs that often incorporate protection against dust, moisture, and impact according to industrial standards.

From an economic perspective, the long-term benefits of implementing a reliable wireless jog pendant system contribute to reduced operational costs. The elimination of cable replacement and repair expenses represents one tangible saving, while the potential for reduced downtime through improved operator efficiency provides additional value. The enhanced safety features can contribute to lower incident rates and associated costs, while the flexibility in operation often translates to faster completion times for tasks requiring multiple positioning adjustments. These factors combine to create a compelling case for the adoption of wireless control technology in modern industrial applications where productivity and safety are parallel priorities.

Phone

Online

Message

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

Phone