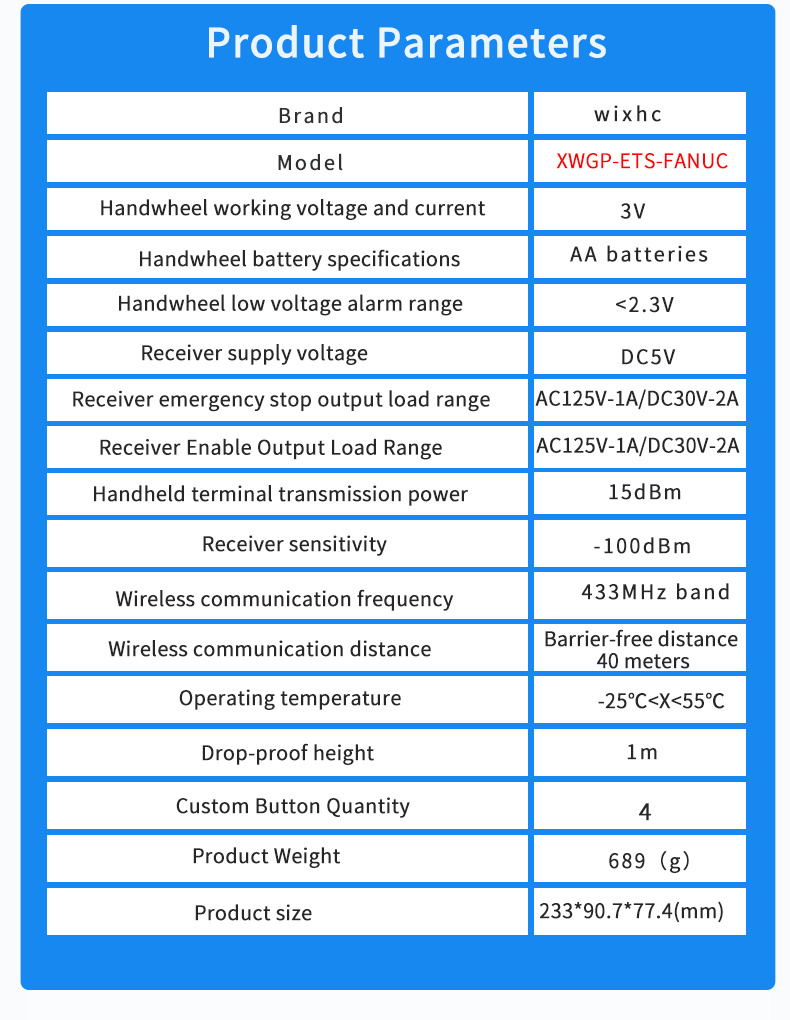

WiXHC Wireless MPG Pendant Control for Fanuc System Real Time Display the Workpiece's Coordinates XWGP-ETS-FANUC 6axis with 6 Customization Buttons

Keyword:

newest MPG Pendant Control

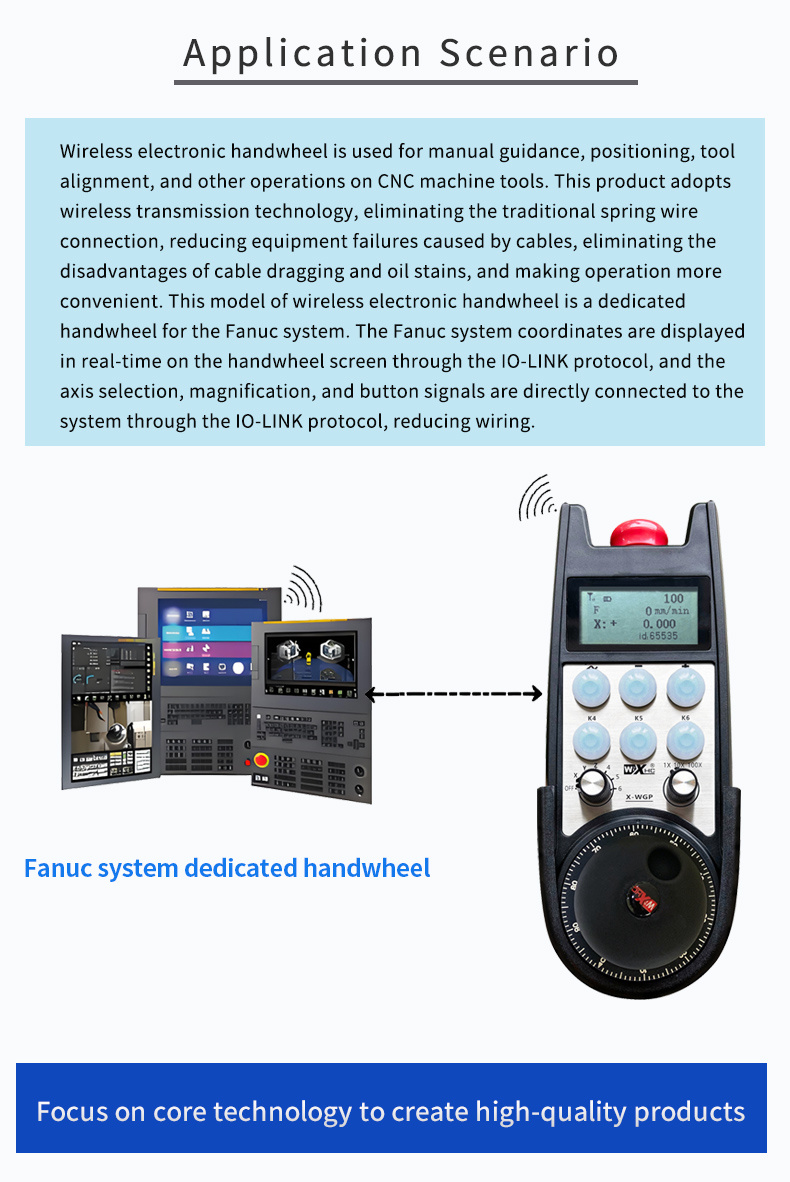

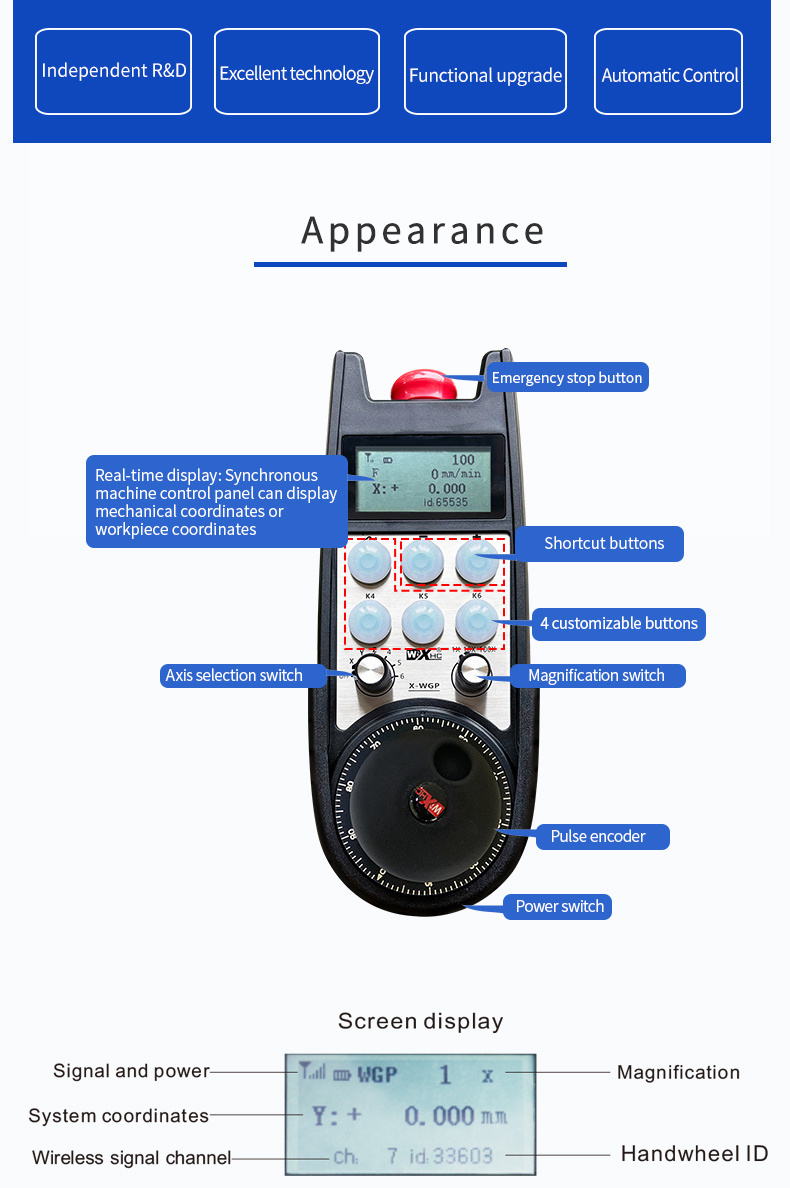

The MPG Pendant Control is a highly responsive manual input device designed to enhance precision and efficiency in CNC machining operations. Widely used on CNC milling machines, lathes, and machining centers, the MPG Pendant Control allows operators to manually jog machine axes with exceptional accuracy. By integrating the MPG Pendant Control into daily operations, users gain finer control over positioning, setup, and alignment tasks, reducing setup time while improving overall machining quality. Its ergonomic design ensures comfortable long-term use, making the MPG Pendant Control an essential accessory for modern workshops.

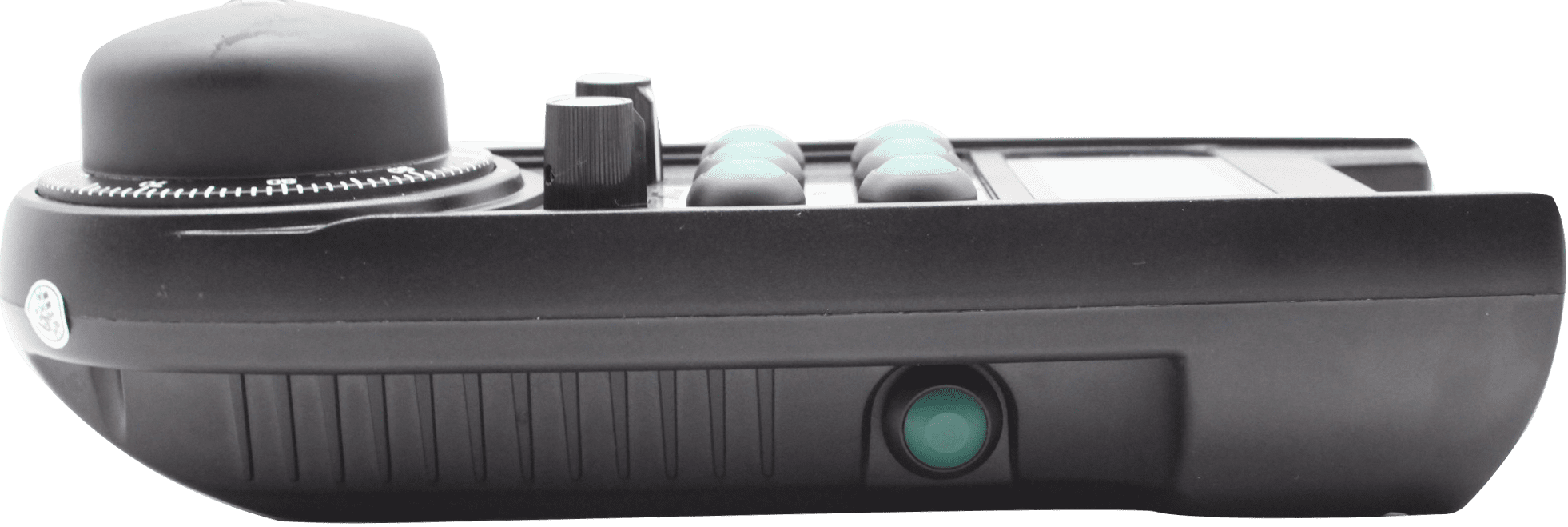

Built with durability and reliability in mind, the MPG Pendant Control typically features a robust handwheel encoder, multiple axis selection switches, and function buttons that simplify complex operations. The MPG Pendant Control enables smooth incremental movement, allowing operators to make micro-adjustments during tool setting or workpiece calibration. Thanks to its clear labeling and intuitive layout, even new operators can quickly become familiar with the MPG Pendant Control, minimizing training costs and operational errors.

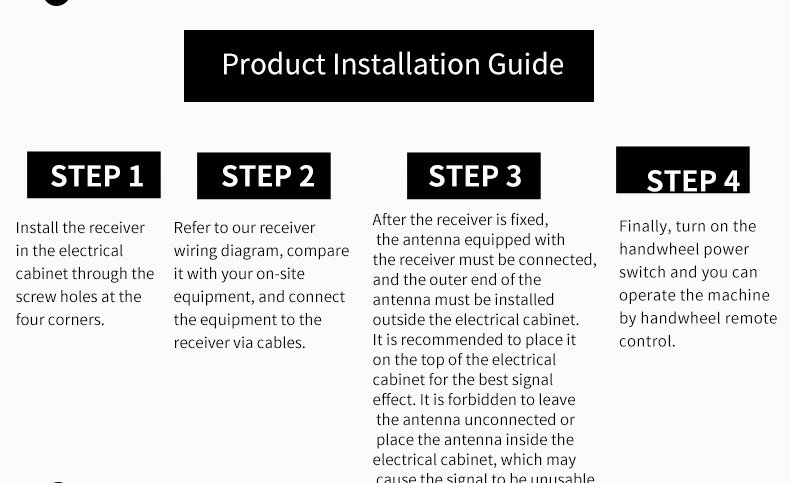

Another major advantage of the MPG Pendant Control is its compatibility with a wide range of CNC control systems. Whether integrated into retrofit projects or new machine installations, the MPG Pendant Control provides flexible connectivity options to meet different control requirements. Its stable signal transmission ensures accurate feedback, helping maintain consistent machining performance. As production demands continue to increase, the MPG Pendant Control stands out as a practical solution for achieving precision, safety, and productivity in CNC environments.

XWGP-ETS-FANUC-Wireless MPG Pendant Features,Real Time Display the Workpiece's Coordinates,only for Fanuc System Use .

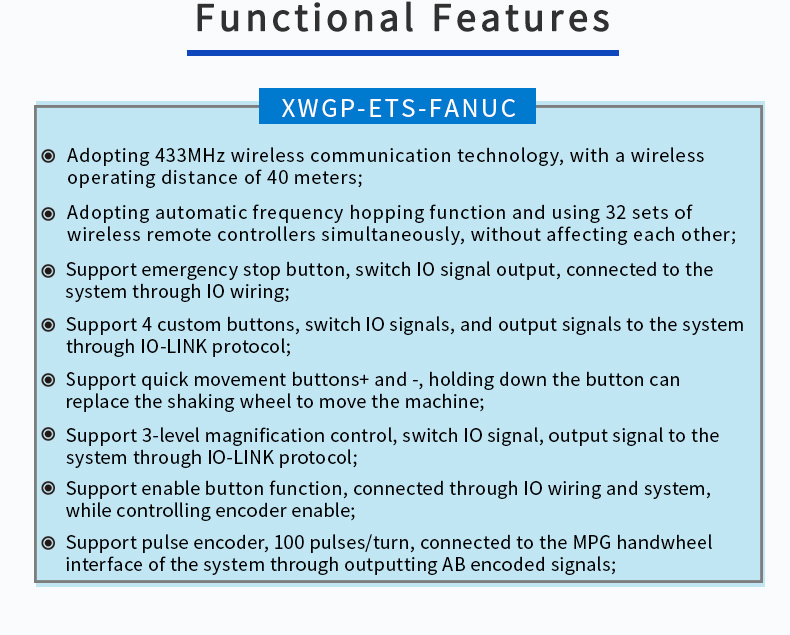

Adopting 433MHZ wireless communication technology, the wireless operationdistance is 40 meters.

1) With automatic freauency hoppina function, 32 sets of wireless remote controllerscan be used at the same time without afecting each other

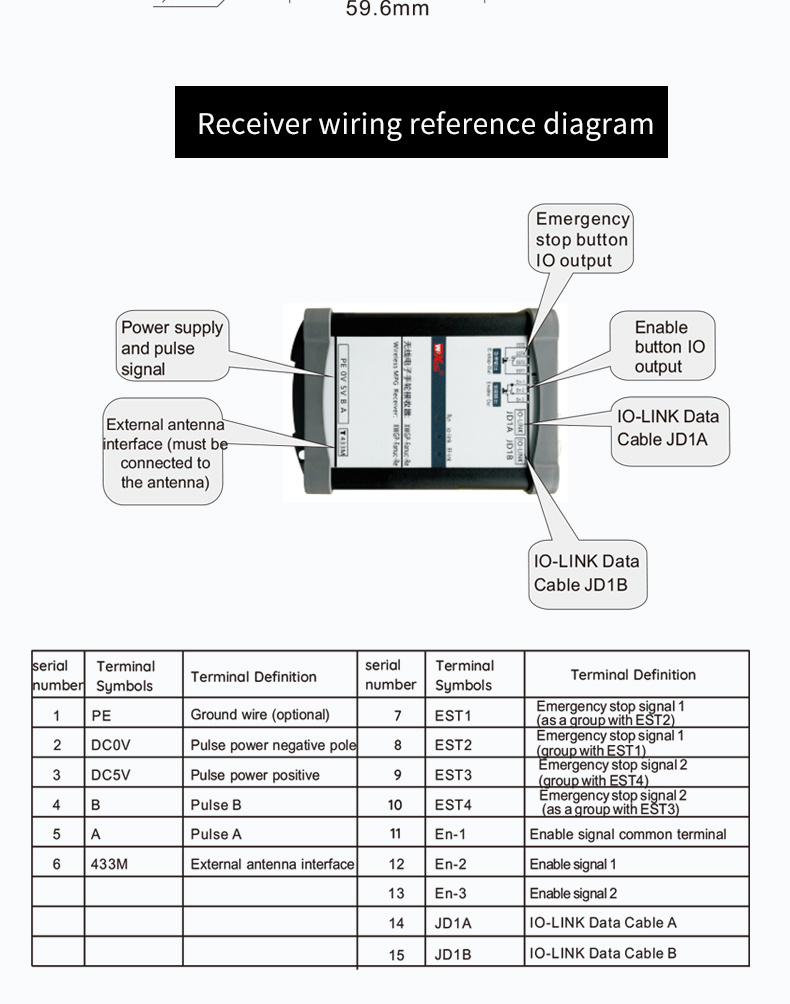

2)Supports emergency stop button, switch l0 signal output, and connect to thesystem through l0 wiring.

3)Supports 1X,10X,100X.Supports switch 10 sianal, and outputs sianals to the system via10-LINK protocol.

4)Supports 6-axis control, switch 10 signals, and outputs signals to the system througl10-LINK protocol.

5)Supports 6 custom buttons, switch 10 signals, and outputs signals to the system viaI0-LlNK protocol.

6) Supports the enable button function, which can control the encoder enable at thesame time through l0 wiring and system connection.

7)Supports pulse encoder, 100 pulses/turn, and connects to the system MPG handwheelinterface by outputting AB encoding signals

Real-time display: synchronousmachine control panel candisplay machine coordinatesor workpiece coordinates

Wireless electronic handwheels can perfectly replace all functions of traditional wired handwheels, support all CNC system brands with handwheel interfaces, and have been widely used in CNC machining centers, CNC vertical lathes, CNC milling machines, large gantry machine tools, CNC cutting machines, CNC laser cutting machines and other equipment.

Wireless electronic handwheel products include enhanced wireless electronic handwheels, real-time display wireless electronic handwheels, professional wireless electronic handwheels, and basic wireless electronic handwheels. So far, more than 40 products in this series have been independently developed.

Phone

Online

Message

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

Phone