WiXHC China Manufacturer Direct Sale Wireless CNC Tool Remote Controller DWGP with Charging model MPG pendant control Support 6-12 axis and 6 Customs Function Buttons Remote Control Distance 80mts

Keyword:

MPG Pendant Control suppliers

WiXHC Wilress Electronic CNC Handwheel CNC Control Pendant with Rechargeable Functions (Model:DWGP)

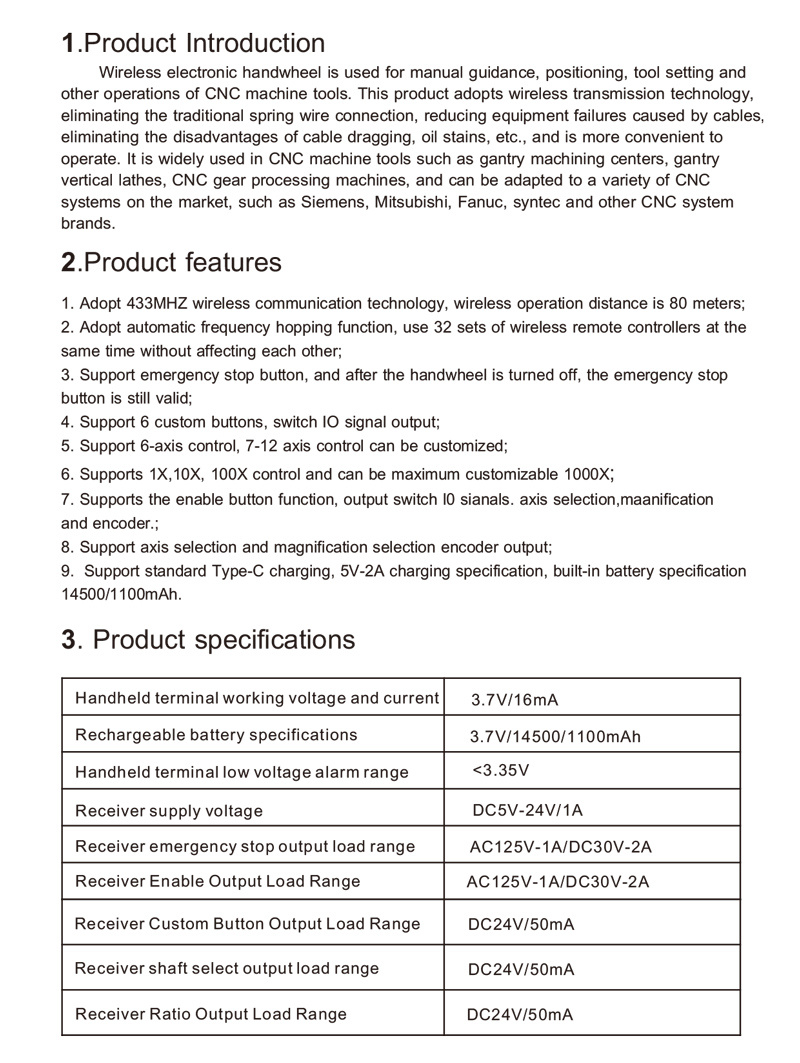

Wireless electronic handwheel is used for manual guidance, positioning, tool setting and

other operations of CNC machine tools. This product adopts wireless transmission technology,

eliminating the traditional spring wire connection, reducing equipment failures caused by cables,

eliminating the disadvantages of cable dragging, oil stains, etc., and is more convenient to

operate. It is widely used in CNC machine tools such as gantry machining centers, gantry

vertical lathes, CNC gear processing machines, and can be adapted to a variety of CNC

systems on the market, such as Siemens, Mitsubishi, Fanuc, syntec and other CNC system

brands.

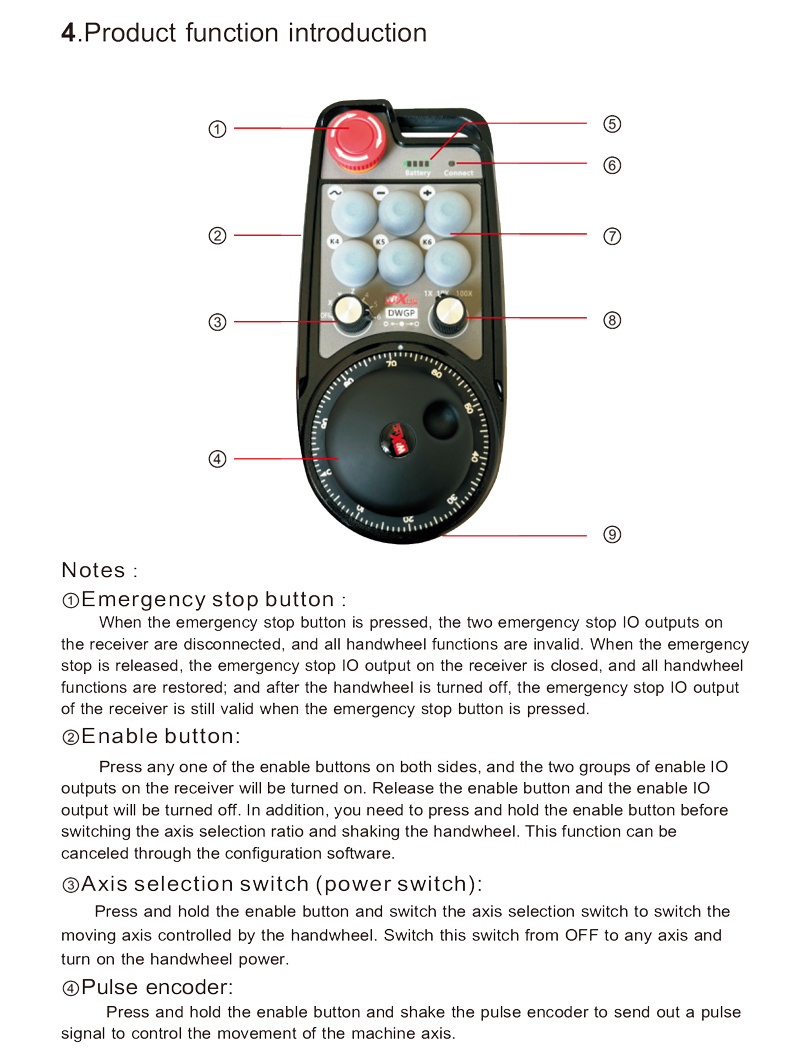

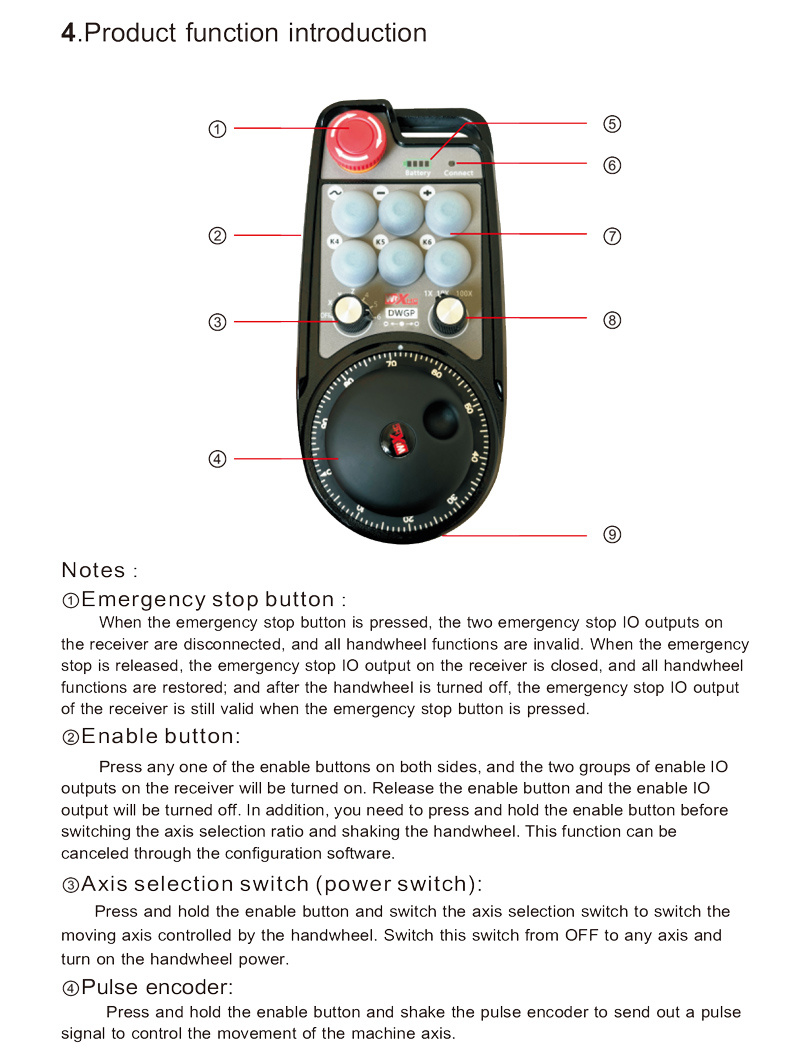

The design and ergonomics of modern MPG pendant controls are focused on user-centric operation. Typically featuring a robust, hand-held enclosure with a rotary pulse generator, axis selection switches, and feedrate override dials, these devices are built for durability and intuitive use in industrial environments. The tactile feedback from the handwheel allows for precise control, while the logical layout of buttons and selectors enables quick mode changes without diverting attention from the machine itself. This thoughtful design minimizes operator fatigue and streamlines the workflow.

In conclusion, the MPG pendant control remains a cornerstone of practical and efficient workshop operation. Its advantages in enhancing setup precision, providing unparalleled operational flexibility, improving safety during manual control and training, and offering ergonomic design solidify its role. For tasks ranging from simple positioning to the intricate setup of complex machining centers, the MPG pendant control proves to be an extension of the operator's skill, enabling greater control, efficiency, and confidence in modern manufacturing processes.

Phone

Online

Message

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

Phone