XHC Brand ZTWGP wireless JOG pendant 6axis MPG Handwheel Pendant with Customs Functions Buttons for Various of CNC Machines and CNC Systems like Fanuce Siemens Masso Fagor etc

Keyword:

wireless Jog Pendant exporter

wireless Jog Pendant

XHC Factory Direct Slae Manual Pulse Generator Handwheel Mpg for CNC Lathe FANUC Mitsubishi Siemens Higerman Fagor etc CNC System use

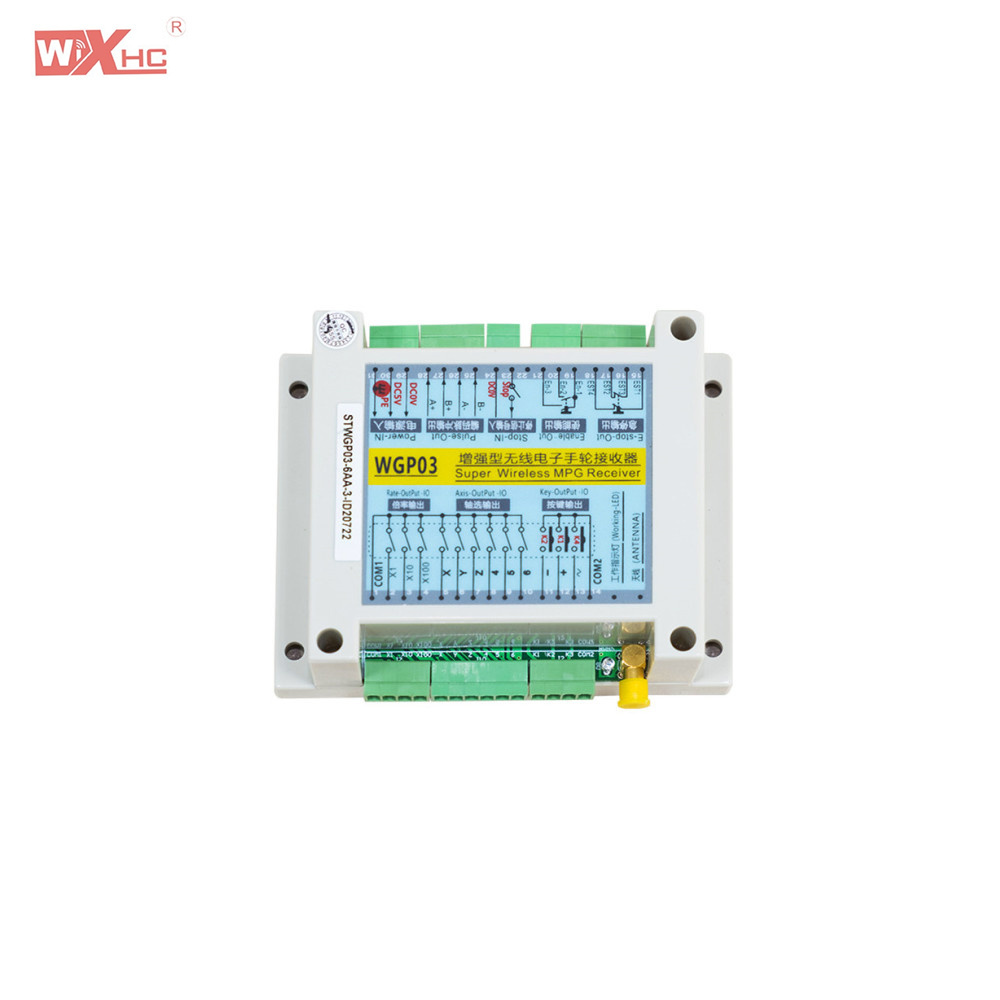

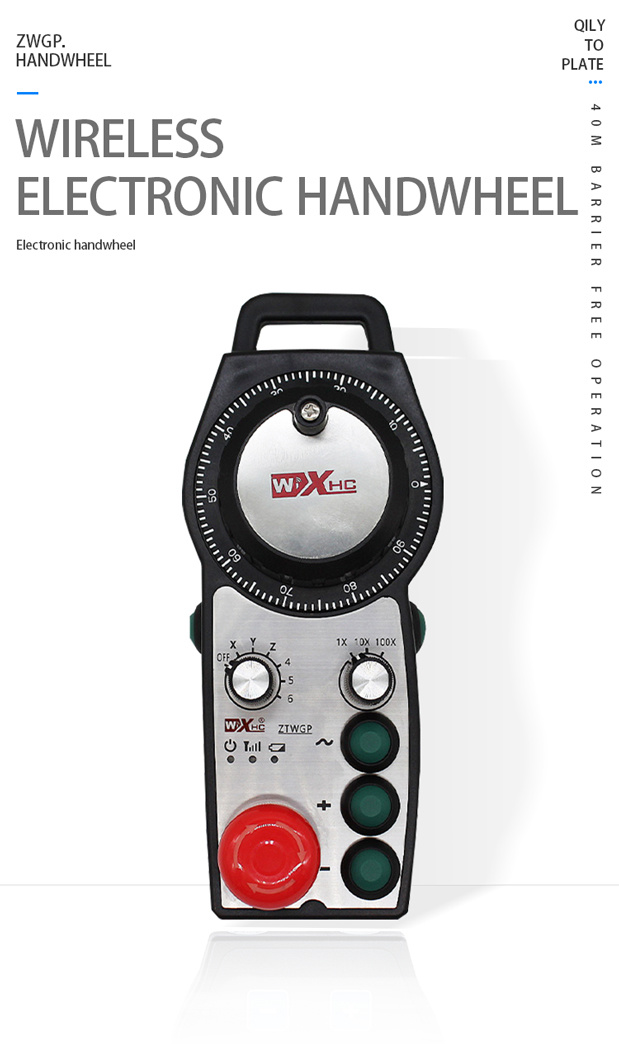

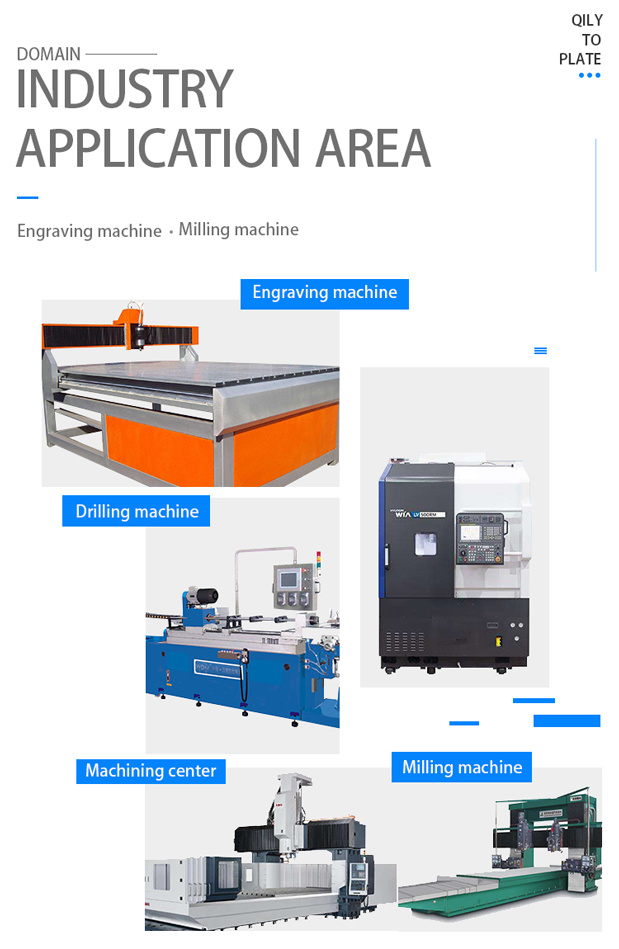

This product is a manual pulse generator used with CNC machine tools. It has been widely used in fields such as CNC machine tools, CNC lathes, machining centers, CNC engraving and milling machines. This product uses wireless transmission technology, eliminating the need for traditional spring wire connections, reducing equipment failures caused by cables, eliminating cable drag, oil and other contamination, and making operation more convenient. The product package includes the receiver and wireless electronic handwheel. The receiver is connected to the CNC equipment through a network cable, and the electronic handwheel (hand pulse generator) is connected and communicated with the receiver through wireless transmission technology. The operator holds the handwheel and can get rid of the connection constraints of the spring wire and move freely. For large-scale gantry milling, CNC lathes, traveling machine tools, cutting and other applications, it brings great convenience and improves work efficiency.

Supports various system brands such as Siemens, Mitsubishi, Fanuc, Taiwan Xindai, Baoyuan, Fagor, Huazhong CNC, Guangzhou CNC, and other CNC systems that support handwheel interfaces.

Features

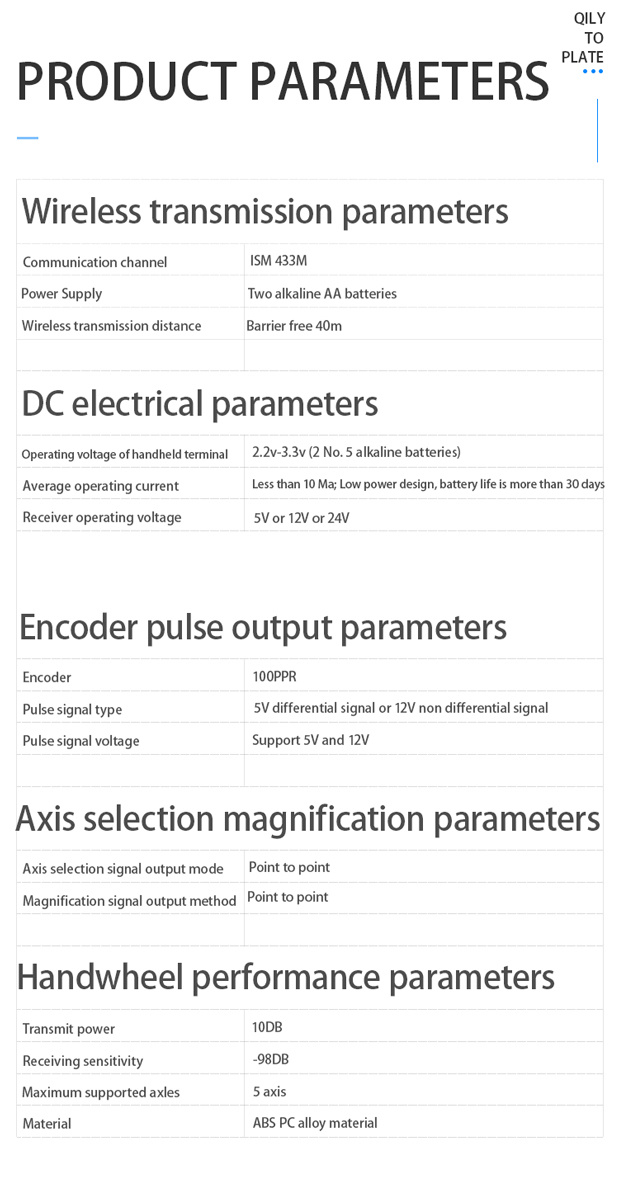

1. Using the 433MHZ wireless communication frequency band, the wireless operating distance is 40 meters;

2. Adopt automatic frequency hopping function and use 32 sets of wireless handwheels at the same time without affecting each other;

3. Supports emergency stop button and 3 custom button switch outputs;

4. Supports 6axis selections with 3-speed magnification.Axis selection and magnification switches support various signal types such as binary coding, point-to-point, gray code, etc.;

5. Supports 5V differential pulse signal, 24V pulse signal and other pulse signal types;

6. Low power consumption design, 2 AA batteries can be used for more than 1 month;

7. Supports external extension antenna, , suitable for various machine tool installation environments, ensuring signal stability;

Phone

Online

Message

If you have any suggestions or feedback on our company, please fill in the relevant information on this page and submit it. A staff member will contact you in time, or please call us directly.

Phone